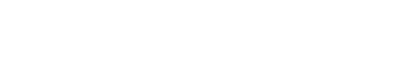

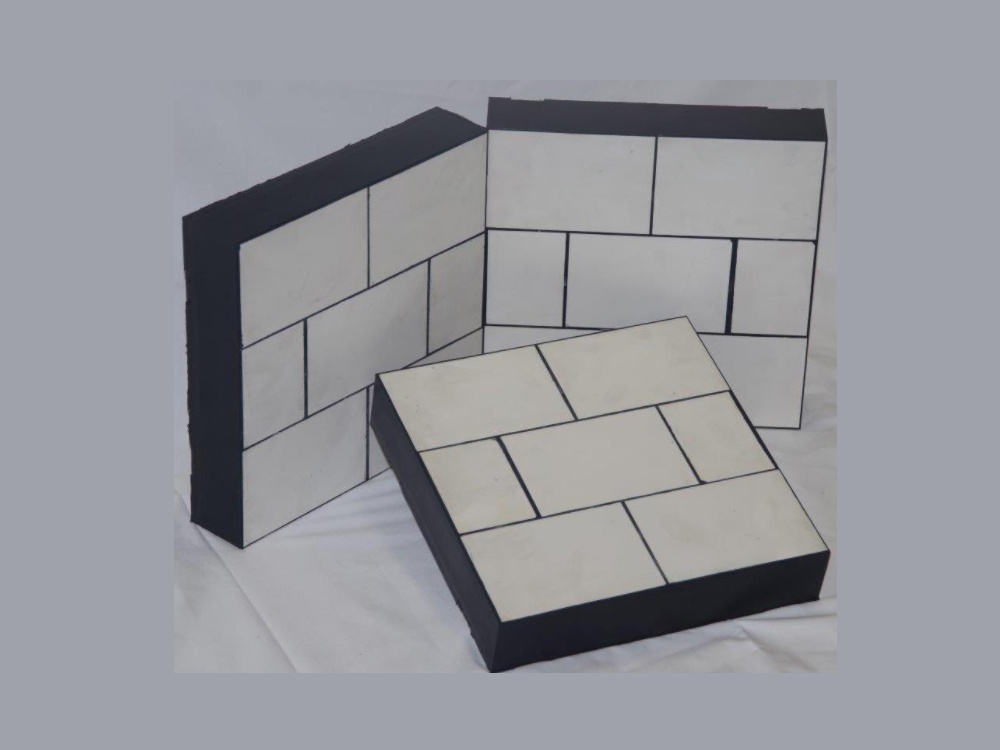

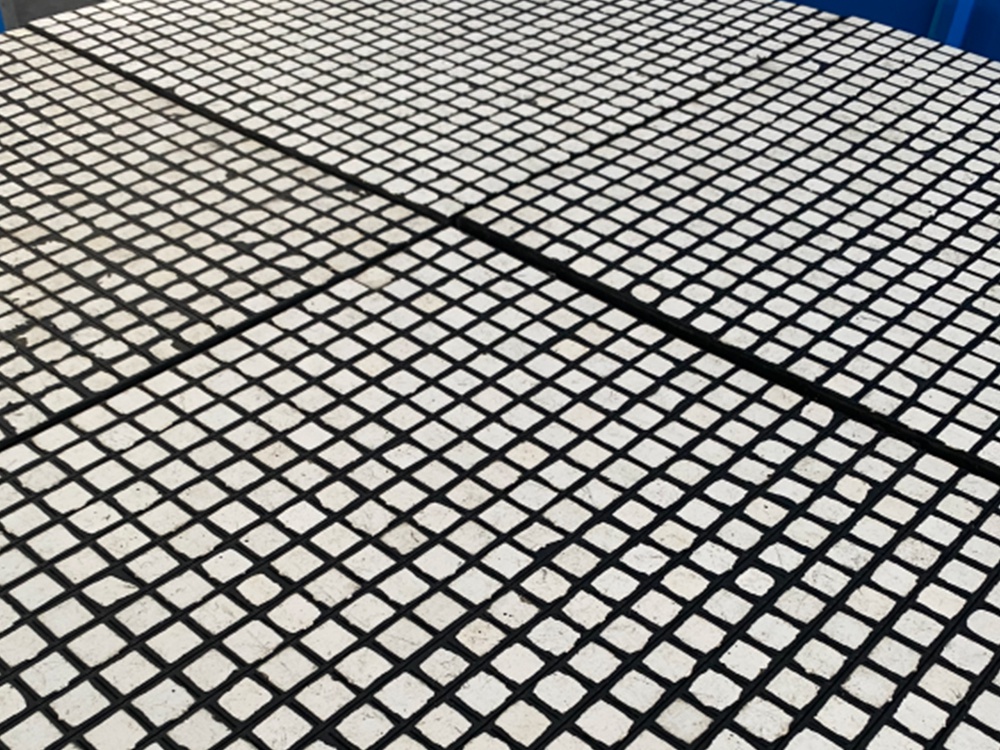

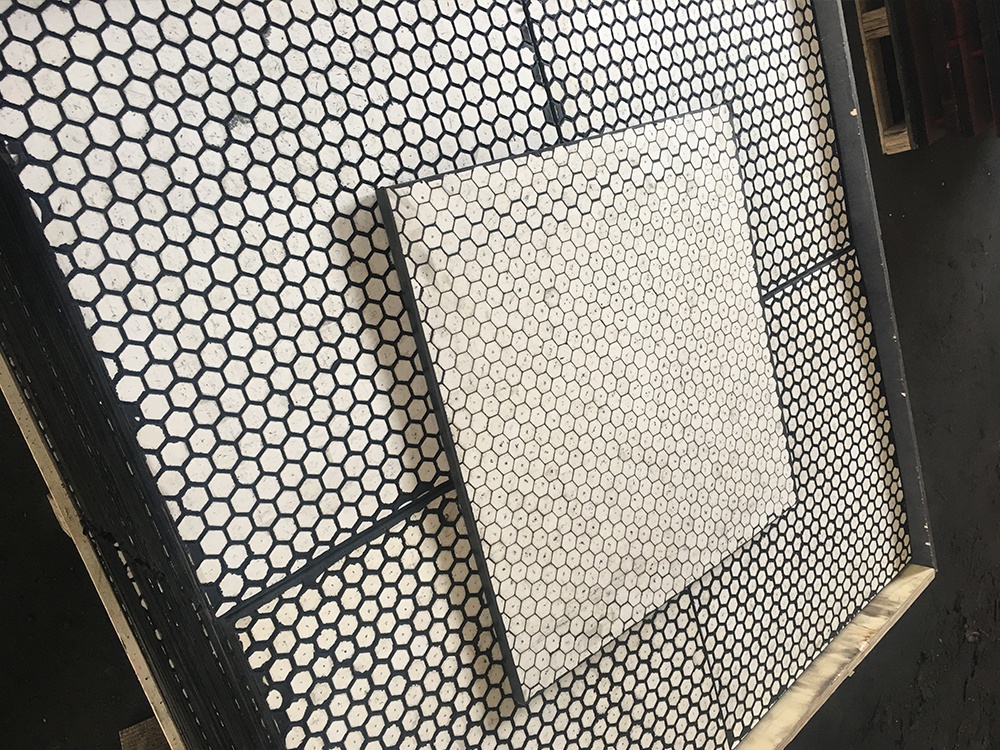

Ceramic Lined Rubber Panel

Application:

High alumina ceramic has excellent abrasion resistant performance. Rubber has excellent impact resistance. The combination of rubber and ceramic has both good abrasion resistance and impact resistance. We are specializing in supplying the high quality ceramic lining, proving total solution to the wear problem for various industries such mining, power plant, steel plant etc.

Dimension:

|

Panel Size |

200×200、250×250、400×400、500×500、600×600 |

|

Ceramic size |

Ceramic tiles are available from 10x 10 mm to 100 x 150 mm; thickness of ceramic tile can be from 1.5 mm to 50 mm. |

|

Alloy Steel Size |

alloy steel plate with thickness ranging from 3 mm to 10 mm |

|

Rubber Thickness |

Depends upon the impact stress expected. |

|

Remark |

metal+rubber+ceramic / rubber+ceramic plain surface or spherical surface. The steel bolt also available upon requests |

Remark: 92%, 95%, ZTA, SISIC bonded rubber all is available.

Specifications of Rubber:

|

Item |

Data |

|

|

Tensile Strength |

16MPa |

|

|

Break Extension |

450-500% |

|

|

Shore Hardness |

60±5 |

|

|

Break permanent deformation |

30% |

|

|

Main composition |

Natural Rubber+SBR |

|

|

Peel strength between rubber and ceramic/rubber and steel |

6MPa |

|

|

Bonding Strength between rubber and ceramic |

4MPa |

|

Advantage:

(1) Rubber and ceramic combination is very good for both sliding and impact abrasions

(2) Reduces shutdown time and reduce the cost

(3) Sound insulation due to the rubber